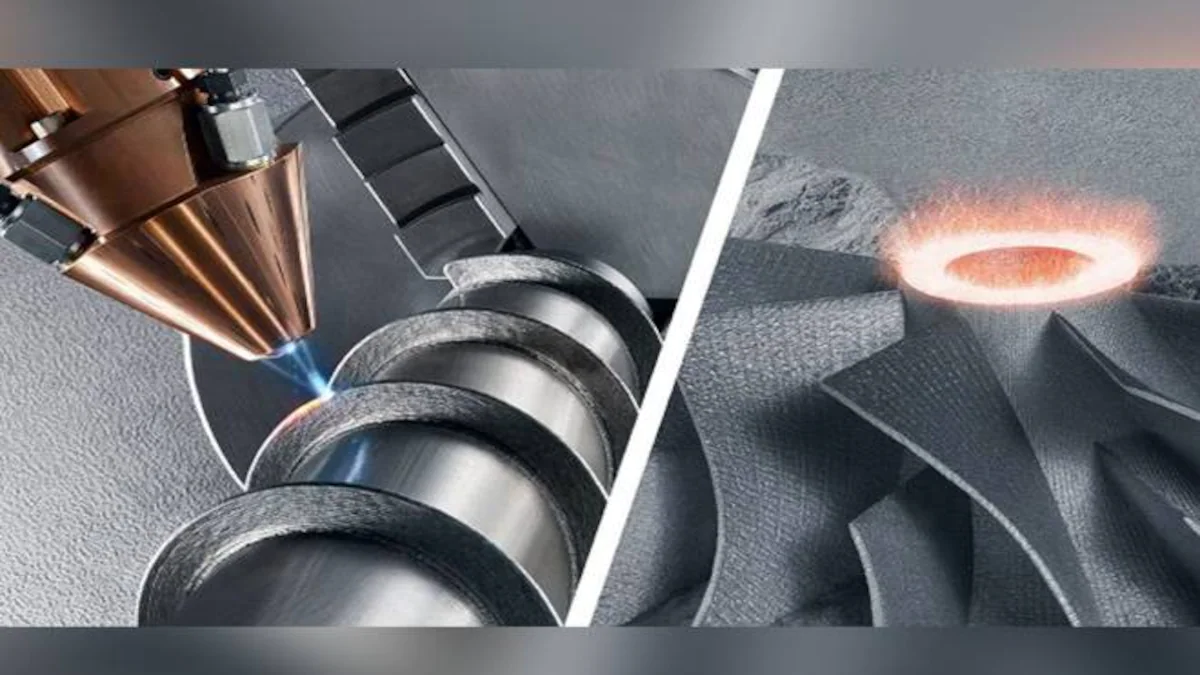

Manufacturing is transforming. One of the biggest shifts is the change to a design-driven manufacturing process, courtesy of additive manufacturing.

In additive manufacturing, successive layers of material are laid down under computer control to create a three-dimensional object. It has the potential to transform manufacturing through expanding design freedom, reducing time to market, bringing production closer to demand, and improving industrial sustainability.

How AM can help India’s Manufacturing Industry (Benefits over Traditional Manufacturing)

Additive manufacturing is a natural fit for Indian manufacturers due to its ability to create customized, labor-intensive parts that require non-standard alloys, tooling, and ceramic materials.

Over the years, many factors like government support, funding, investments, skilled talent, and access to novel ideas have played an important role in the growth of the additive manufacturing industry in a country.

Additive manufacturing has several advantages over conventional manufacturing; here are some advantages of additive manufacturing over conventional manufacturing –

- Accelerated Prototyping

Additive manufacturing expands the possibilities for product development by increasing the number of prototypes that can be created with each new revision before committing to a production run. This way, there is less room for error in the development process, which greatly reduces costs compared to traditional methods.

And because prototypes made by using additive manufacturing can be changed digitally – rather than by physically altering them – changes are made much more quickly, allowing manufacturers to deliver quickly even with short notice.

- Customisation and Precision

With lesser cost and time constraints, creative freedom and design innovation are made easier with additive manufacturing. As altering the original design specifications gets easier, businesses gain more opportunities to provide customized designs to their clients. Furthermore, additive manufacturing helps manufacturers produce parts with complex geometries and intricate designs. This enhanced precision and accuracy ultimately lead to better-quality products for consumers.

- Energy-Efficient Tools

Traditional manufacturing often needs auxiliary equipment with higher energy demands to function properly. On the other hand, additive manufacturing needs fewer resources and lesser ancillary tools, which leads to lesser manufacturing waste. As lesser energy is needed for extraction of raw materials in additive manufacturing, overall energy usage is reduced to a big extent.

- Environmental Benefits

Additive manufacturing can cut time and the costs of producing a part for manufacturers by making it possible to build it up layer by layer rather than cut away at the parts like in traditional manufacturing. Layers are built on each other, and excess material that didn’t make it into the final product is avoided during this process, too. This can greatly reduce the chances of mistakes being passed along or made while building up layers.

- Judicial Inventory and Stock Management

Additive manufacturing reduces inventory by removing the need to hold surplus inventory stock and associated carrying costs. Instead of producing components, you’ll get printed on-demand, meaning there is no over-production, no unsold finished goods, and lesser stock needed as 3D printing uses material that is only used as per your need.

This is not an exhaustive list of benefits of additive manufacturing over traditional methods. There are many more such as parts and production flexibility, supply chain improvement and reverse engineering to reproduce legacy parts which are no longer in production. Major transformations also open up far greater opportunities for creativity to play a role in the process and excellent examples include 3D printed jewelry and fashion accessories.

Conclusion

Additive manufacturing is an emerging technology that has the potential to disrupt the manufacturing industry. It is a technology that can be used in a wide spectrum of industries from aerospace, automotive, healthcare, and consumer goods to even the construction industry. It has myriad applications and benefits over conventional manufacturing methods such as less waste, energy efficiency, quicker prototyping, and better customization for customers.

In India, the technology is still in its infancy stage, but it has the potential to transform manufacturing through expanding design freedom, reducing time to market, bringing production closer to demand, and improving industrial sustainability.